projekte:3d-printing:anycubic-mega-s:klipper

Inhaltsverzeichnis

Anycubic Mega S - Klipper Einrichtung und Konfiguration

Klipper Config Check

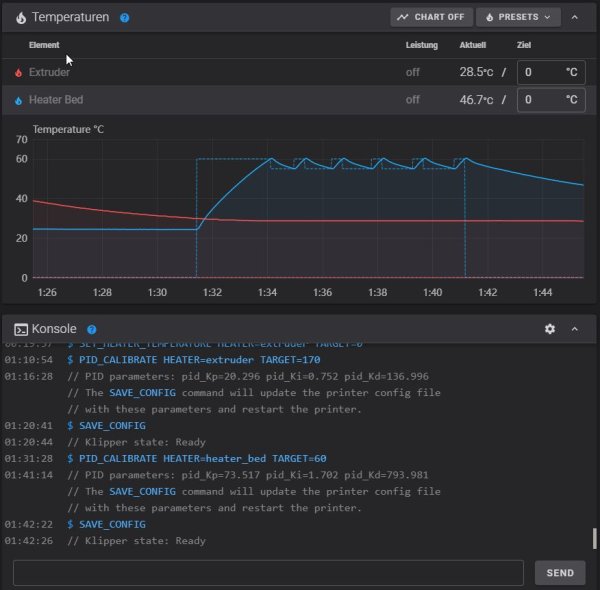

Calibrate PID settings

Um die Temperatur des Extruder zu kalibrieren führt man den ersten Befehl aus, wartet ab bis der Kalibriervorgang abgeschlossen wurde und speichert die gefundenen Werte in der printer.cnf ab (passiert automatisch und wird am Ende eingefügt).

PID_CALIBRATE HEATER=extruder TARGET=170 SAVE_CONFIG

Um die Temperatur des Printbed zu kalibrieren führt man den ersten Befehl aus, wartet ab bis der Kalibriervorgang abgeschlossen wurde und speichert die gefundenen Werte in der printer.cnf ab (passiert automatisch und wird am Ende eingefügt).

PID_CALIBRATE HEATER=heater_bed TARGET=60 SAVE_CONFIG

Basiskonfiguration

Basiskonfiguration (Beispiel) für einen Anycubic Mega S ohne Modifikationen / Originalzustand

- printer.cfg

- # This file contains pin mappings for the Anycubic i3 Mega with

- # Ultrabase from 2017. (This config may work on an Anycubic i3 Mega v1

- # prior to the Ultrabase if you comment out the definition of the

- # endstop_pin in the stepper_z1 section.) To use this config, the

- # firmware should be compiled for the AVR atmega2560.

- # See docs/Config_Reference.md for a description of parameters.

- [stepper_x]

- step_pin: PF0

- dir_pin: PF1

- enable_pin: !PD7

- microsteps: 16

- rotation_distance: 40

- endstop_pin: ^!PE5

- position_min: -5

- position_endstop: -5

- position_max: 210

- homing_speed: 30.0

- [stepper_y]

- step_pin: PF6

- dir_pin: !PF7

- enable_pin: !PF2

- microsteps: 16

- rotation_distance: 40

- endstop_pin: ^!PL7

- position_endstop: 0

- position_max: 210

- homing_speed: 30.0

- [stepper_z]

- step_pin: PL3

- dir_pin: !PL1

- enable_pin: !PK0

- microsteps: 16

- rotation_distance: 8

- endstop_pin: ^!PD3

- position_endstop: 0.0

- position_max: 205

- homing_speed: 5.0

- [stepper_z1]

- step_pin: PC1

- dir_pin: !PC3

- enable_pin: !PC7

- microsteps: 16

- rotation_distance: 8

- endstop_pin: ^!PL6

- [extruder]

- step_pin: PA4

- dir_pin: !PA6

- enable_pin: !PA2

- microsteps: 16

- rotation_distance: 34.557

- nozzle_diameter: 0.400

- filament_diameter: 1.750

- heater_pin: PB4

- sensor_type: ATC Semitec 104GT-2

- sensor_pin: PK5

- #control: pid

- #pid_Kp: 15.717

- #pid_Ki: 0.569

- #pid_Kd: 108.451

- min_temp: 0

- max_temp: 245

- [heater_fan extruder_fan]

- pin: PL5

- [heater_bed]

- heater_pin: PH5

- sensor_type: EPCOS 100K B57560G104F

- sensor_pin: PK6

- #control: pid

- #pid_Kp: 74.883

- #pid_Ki: 1.809

- #pid_Kd: 775.038

- min_temp: 0

- max_temp: 110

- [fan]

- pin: PH6

- [mcu]

- serial: /dev/serial/by-id/usb-Silicon_Labs_CP2102_USB_to_UART_Bridge_Controller_0001-if00-port0

- [printer]

- kinematics: cartesian

- max_velocity: 300

- max_accel: 3000

- max_z_velocity: 10

- max_z_accel: 60

- [heater_fan stepstick_fan]

- pin: PH4

- # additional manual config

- # see https://docs.fluidd.xyz/configuration/initial_setup

- [virtual_sdcard]

- path:/home/pi/printer_data/gcodes

- [display_status]

- [pause_resume]

- [gcode_macro PAUSE]

- description: Pause the actual running print

- rename_existing: PAUSE_BASE

- # change this if you need more or less extrusion

- variable_extrude: 1.0

- gcode:

- ##### read E from pause macro #####

- {% set E = printer["gcode_macro PAUSE"].extrude|float %}

- ##### set park positon for x and y #####

- # default is your max posion from your printer.cfg

- {% set x_park = printer.toolhead.axis_maximum.x|float - 5.0 %}

- {% set y_park = printer.toolhead.axis_maximum.y|float - 5.0 %}

- ##### calculate save lift position #####

- {% set max_z = printer.toolhead.axis_maximum.z|float %}

- {% set act_z = printer.toolhead.position.z|float %}

- {% if act_z < (max_z - 2.0) %}

- {% set z_safe = 2.0 %}

- {% else %}

- {% set z_safe = max_z - act_z %}

- {% endif %}

- ##### end of definitions #####

- PAUSE_BASE

- G91

- {% if printer.extruder.can_extrude|lower == 'true' %}

- G1 E-{E} F2100

- {% else %}

- {action_respond_info("Extruder not hot enough")}

- {% endif %}

- {% if "xyz" in printer.toolhead.homed_axes %}

- G1 Z{z_safe} F900

- G90

- G1 X{x_park} Y{y_park} F6000

- {% else %}

- {action_respond_info("Printer not homed")}

- {% endif %}

- [gcode_macro RESUME]

- description: Resume the actual running print

- rename_existing: RESUME_BASE

- gcode:

- ##### read E from pause macro #####

- {% set E = printer["gcode_macro PAUSE"].extrude|float %}

- #### get VELOCITY parameter if specified ####

- {% if 'VELOCITY' in params|upper %}

- {% set get_params = ('VELOCITY=' + params.VELOCITY) %}

- {%else %}

- {% set get_params = "" %}

- {% endif %}

- ##### end of definitions #####

- {% if printer.extruder.can_extrude|lower == 'true' %}

- G91

- G1 E{E} F2100

- {% else %}

- {action_respond_info("Extruder not hot enough")}

- {% endif %}

- RESUME_BASE {get_params}

- [gcode_macro CANCEL_PRINT]

- description: Cancel the actual running print

- rename_existing: CANCEL_PRINT_BASE

- gcode:

- TURN_OFF_HEATERS

- CANCEL_PRINT_BASE

- [gcode_macro START_PRINT]

- gcode:

- G28 X0 Y0 ; move X/Y to min endstops

- G28 Z0 ; move Z to min endstops

- G1 Z20 Y5 F500 ; move nozzle away from bed

- G92 E0 ; zero the extruded length

- G1 E2 F2400 ; extrude 5mm of feed stock

- G92 E0 ; zero the extruded length again

- M117 Printing...

- [gcode_macro END_PRINT]

- gcode:

- M400 ; Clear Buffer

- M104 S0 ; turn off extruder

- M140 S0 ; turn off bed

- G10 ; retract

- G91 ; relative positioning

- G1 E-0.03 Z1.00 X20.0 Y20.0 ; move nozzle to remove stringing

- M106 S0 ; turn off fan

- G1 Z20 ; move nozzle up 20mm

- G90 ; absolute positioning

- G0 X0 Y175 ; park nozzle at rear

- M84 ; steppers off

- G4 P250 ; dwell

- _TIMELAPSE_NEW_FRAME

- M300 ; Beep

- #*# <---------------------- SAVE_CONFIG ---------------------->

- #*# DO NOT EDIT THIS BLOCK OR BELOW. The contents are auto-generated.

- #*#

- #*# [extruder]

- #*# control = pid

- #*# pid_kp = 20.315

- #*# pid_ki = 0.748

- #*# pid_kd = 137.890

- #*#

- #*# [heater_bed]

- #*# control = pid

- #*# pid_kp = 73.517

- #*# pid_ki = 1.696

- #*# pid_kd = 796.738

projekte/3d-printing/anycubic-mega-s/klipper.txt · Zuletzt geändert: 2023/06/22 15:53 von daniel